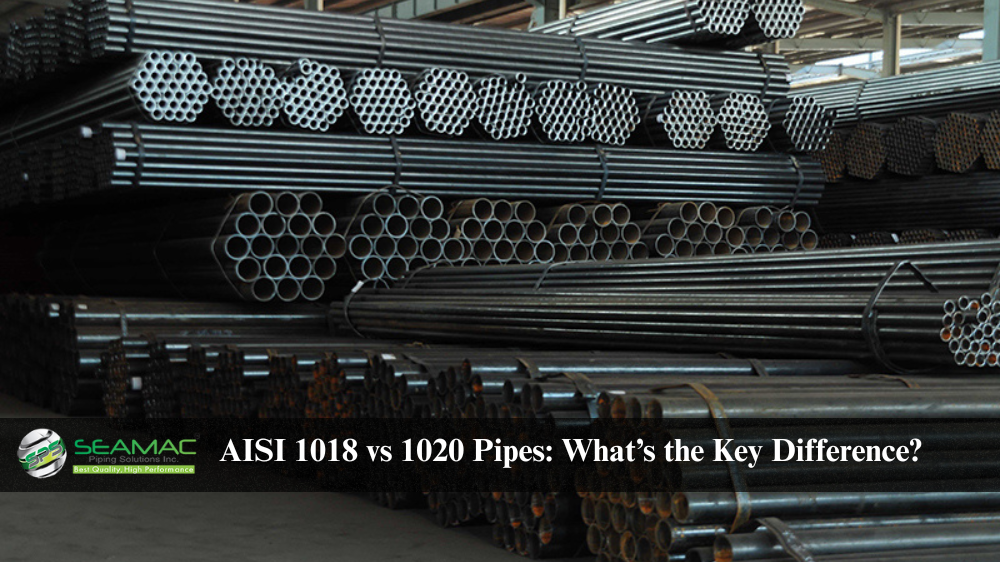

When it comes to choosing the right steel pipe for industrial, structural, or engineering applications, AISI 1018 and AISI 1020 pipes are two common options. While both belong to the low carbon steel family, they have unique characteristics that make them suitable for different uses. In this blog, we’ll break down the key differences between AISI 1018 and 1020 pipes in simple and easy words to help you make an informed choice.

What is AISI 1018 Pipe?

AISI 1018 is a low-carbon steel grade with good weldability, uniform hardness, and excellent machinability. It contains around 0.18% carbon, which gives it a balance between strength and flexibility. This makes it a popular choice in general-purpose construction, shafts, and machine parts.

What is AISI 1020 Pipe?

AISI 1020 is also a low-carbon steel but has slightly more carbon content around 0.20%. While this difference may seem small, it gives AISI 1020 slightly better strength and hardness compared to 1018, though it’s slightly less machinable.

Key Differences Between AISI 1018 and AISI 1020 Pipes

| Property | AISI 1018 Pipes | AISI 1020 Pipes |

|---|---|---|

| Carbon Content | ~0.18% | ~0.20% |

| Strength | Slightly lower than 1020 | Slightly higher due to more carbon |

| Machinability | Excellent | Good, but slightly less than 1018 |

| Weldability | Very good | Very good |

| Formability | Better formability | Slightly less formable |

| Applications | Ideal for precision parts | Ideal for general-purpose parts |

AISI 1018 Pipes: Features and Applications

Features:

-

High machinability

-

Good weldability and ductility

-

Smooth surface finish

-

Uniform mechanical properties

Common Uses:

-

Shafts and spindles

-

Gears and pins

-

Machine components

-

Structural parts needing precision

AISI 1020 Pipes: Features and Applications

Features:

-

Slightly higher strength than 1018

-

Good weldability

-

Decent machinability

-

Easy to cold form and bend

Common Uses:

-

Automotive parts

-

Tubing and piping

-

Lightly stressed components

-

Agriculture and construction equipment

SAE 1018 Steel Price vs AISI 1020

When it comes to cost, both grades are budget-friendly. However, the SAE 1018 steel price is generally a bit more stable due to its higher demand and availability. AISI 1020 may cost slightly more depending on the form, size, and supplier.

Factors affecting SAE 1018 steel price:

-

Size and shape of the pipe

-

Quantity ordered

-

Current market demand

-

Processing method (cold drawn, hot rolled)

Both types offer good value for money, but your choice depends on whether you need more ease of machining or slightly better strength.

Which One Should You Choose?

Choose AISI 1018 Pipes if:

-

You need high machinability for turning, drilling, or milling

-

You’re manufacturing small, precision components

-

A smooth finish is important

Choose AISI 1020 Pipes if:

-

You require slightly more strength

-

Your application involves forming or shaping

-

You’re working with general structural components

Conclusion

Both AISI 1018 and AISI 1020 pipes offer solid performance for low-carbon steel applications. The main difference lies in the carbon content, which slightly affects strength and machinability. If your priority is precision machining, go for 1018 pipes. If you need a bit more strength and general usability, 1020 pipes are a better pick.

Understanding these small differences can help you avoid problems in fabrication and ensure long-lasting performance in your projects.